INDUSTRIAL ULTRASONIC OR SPRAY PIPE WASHING

Industrial cleaning is necessary because, after processing, pipes contain chips, cutting oils, and metal particles that must be completely removed to avoid malfunctions or contamination. The most effective technologies are:

Ultrasonic cleaning

This method immerses the tubes in a tank containing a cleaning solution (aqueous or solvent), where transducers generate acoustic cavitation. The microbubbles implode against the surfaces, uniformly and gently removing oils, greases, and residues, even inside blind holes or grooves.

Spray cleaning

It uses pressurized jets from multiple nozzles positioned around the pipes, often inside cells with a 360° rotating basket. The combined action of mechanical pressure and detergents removes surface contaminants in minutes.

MODELS THAT WE OFFER FOR PIPE CLEANING

ULTRASONIC OR CONTINUOUS SPRAY DEGREASING

PIPE SYSTEMS WITH POSITIONED OR BULK WASHING

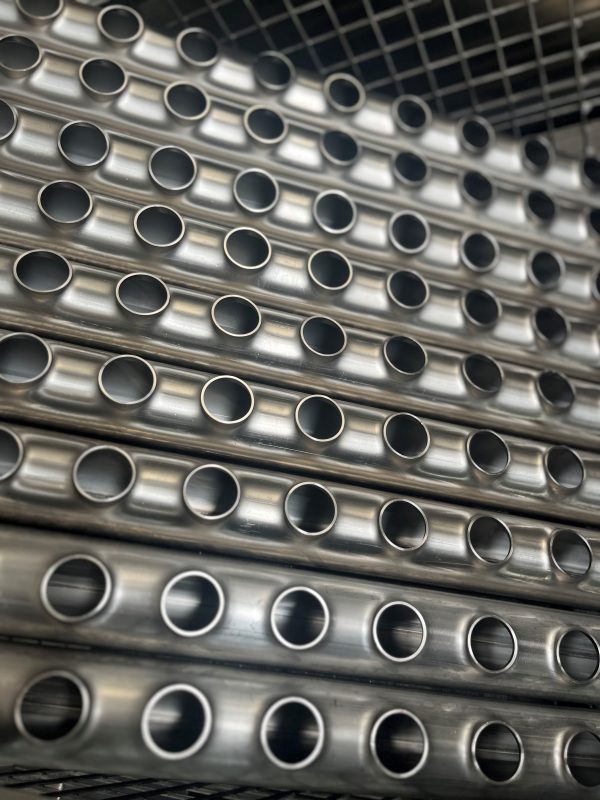

Steel collectors before ultrasonic cleaning

Firearm tube after spray washing