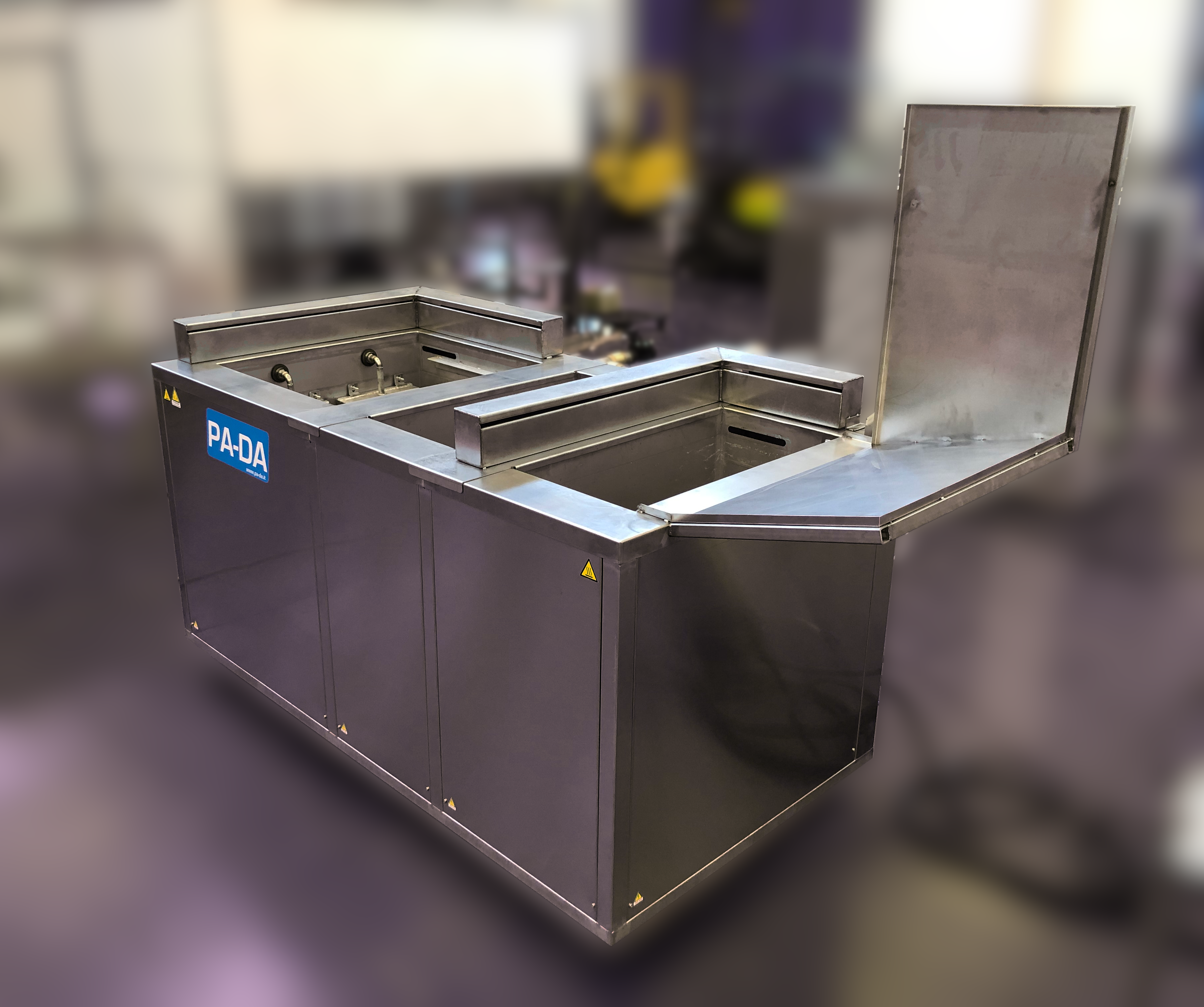

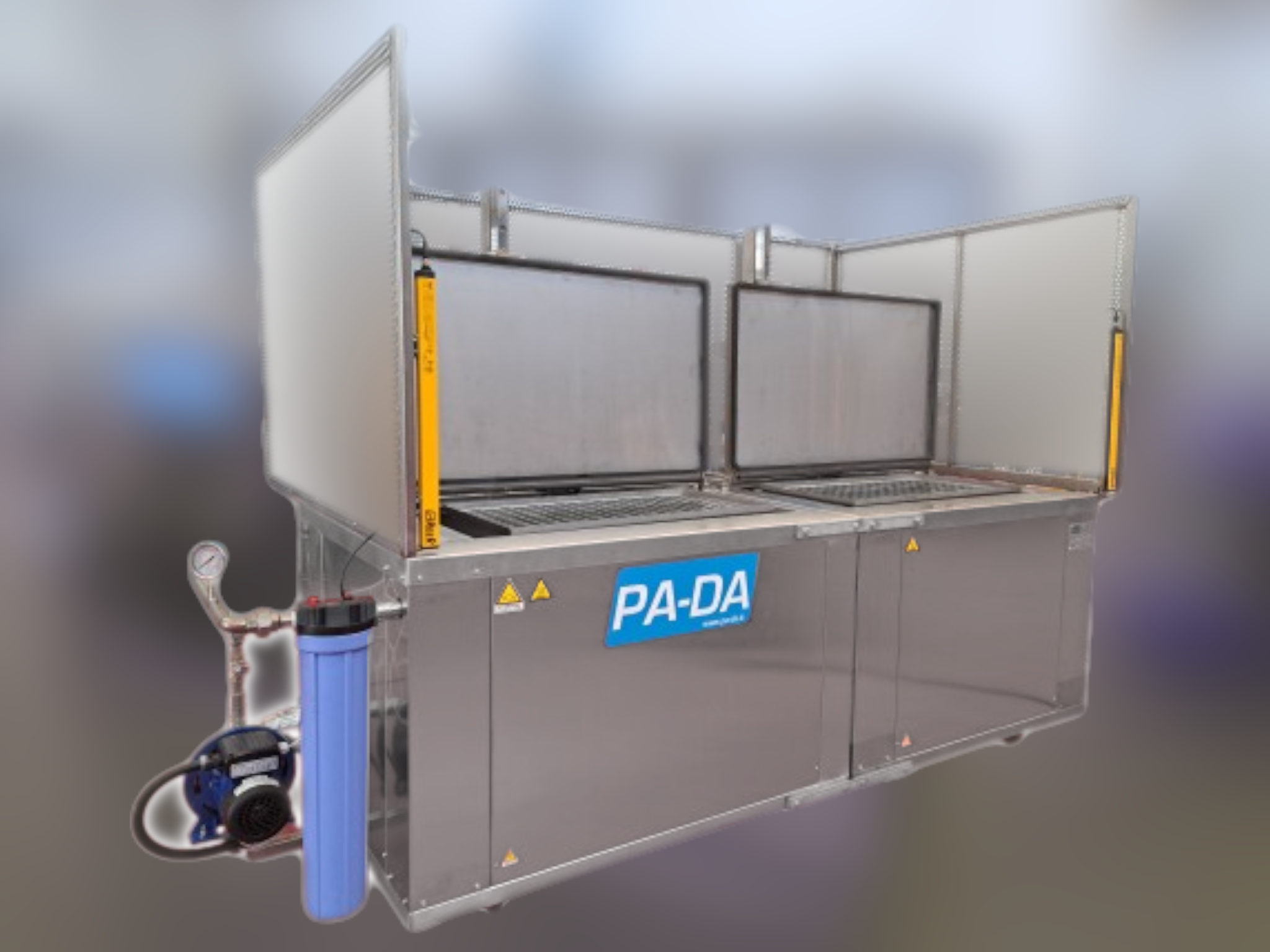

EPTA Man series multi-tank ultrasonic washers with manual or piece transfer system

EPTA MAN series ultrasonic cleaners allow for washing cycles in which the ultrasonic phase is followed by other steps such as rinsing, protection, and drying. Parts can be transferred from one station to another manually or mechanically using hoists or other simple and economical devices. These devices, in addition to allowing the passage of parts between the various stations, also assist with the immersion and extraction phases. For complex geometries or small parts, the cleaners can be equipped with a rotating basket. Ultrasonic cleaners are professional devices designed to perform a thorough and precise wash using ultrasonic technology. They differ from traditional cleaners because they use high-frequency sound waves (generally between 20 and 50 kHz) to generate the physical phenomenon of cavitation in a cleaning liquid. Inside the tank, usually made of stainless steel, piezoelectric transducers transform electrical energy into mechanical vibrations, creating microbubbles that rapidly implode. This implosion produces microscopic jets of water capable of detaching and dissolving impurities, oils, greases, dust, metal, or organic residues from the surfaces of immersed objects. Ultrasonic cleaners are particularly effective on components with complex geometries, blind holes, grooves, or internal surfaces inaccessible with manual or traditional methods. They can be equipped with heating systems, timers, liquid recirculation filters, and automated programs, making them versatile and adaptable to a variety of needs. Their main advantages include high precision, time and detergent savings, uniform treatment, reduced environmental impact, and protection of delicate materials. Ultrasonic cleaners therefore represent an advanced solution for ensuring deep cleaning and reliable results, improving the quality and efficiency of industrial and professional processes. We produce standard models and customized solutions.

RELATED PRODUCTS

CONCESSIONS

INDUSTRY 4.0

INDUSTRY 5.0

KEY FEATURES

Vertical agitation platform

Devices for moving baskets

Drying with filtered hot air

Automatic oil separator

KEY POINTS

standard models from 30 liters to 20,000 liters

long-life armored heating resistors

modular and COMPONENT systems to achieve high cleaning standards

EPTA 03 MAN

Ultrasonic washer plus rinse and manual blowing sectione

EPTA 02 MAN Lifter

Ultrasonic washer plus rinse with manually movable pneumatic platform

EPTA 05 MAN

Industrial ultrasonic washer with demineralized water rinsing and drying sections

EPTA MAN SERIES MANUAL TRANSFER ULTRASONIC WASHERS CATALOGUE MODELS

|

Model series EPTA MAN |

Washing line sequence |

Internal dimensions of the tanks (mm) |

Installed electrical power (KW) |

Single tank capacity (lt) |

|

02 / US-R type 60 |

Ultrasound / Rinsing |

500 x 400 x 300h |

2,6 |

60 |

|

02 / US-R |

Ultrasound / Rinsing |

600 x 400 x 500h |

4,6 |

120 |

|

02 / US-R type 300 |

Ultrasound / Rinsing |

700 x 700 x 600h |

7,2 |

300 |

|

03 US/R/US |

Ultrasound / Rinsing / Ultrasound |

200 x 200 x 750h |

5,2 |

30 |

|

03 / US-RC-F |

Ultrasound / Rinsing / hot Oven |

500 x 400 x 300h |

6 |

60 |

|

03 / US-R-RD |

Ultrasonic / Rinse / Demi-rinse |

400 x 400 x 550h |

2,6 |

80 |

|

03 / US – R – RC |

Ultrasonic / Rinse / Hot Rinse |

700 x 500 x 500h |

5,2 |

175 |

|

03 / US-R-SB |

Ultrasonic / Rinse / Whitening |

800 x 500 x 900h |

14,4 |

360 |

|

03 / US-R-RC type 420 |

Ultrasonic / Rinse / Hot Rinse |

1400 x 400 x 750h |

13,6 |

420 |

|

03 / US-R-RC type 420 |

Ultrasonic / Rinse / Hot Rinse |

800 x 500 x 900h |

18 |

420 |

|

03 / US-R-RC type 720 |

Ultrasonic / Rinse / Hot Rinse |

1200 x 600 x 1000h |

19,4 |

720 |

|

03 / US-R-DW |

Ultrasonic / Rinsing / Dewatering |

1100 x 800 x 1400h |

21,2 |

1230 |

|

04 / SG – US – R -RC |

Hot Degreasing / Ultrasonic – Rinsing – Hot Rinsing |

550 x 550 x 800h |

19,6 |

280 |

|

05 / US – R -RD – F |

Ultrasonic / Rinse / Demi-rinse / Oven |

400 x 400 x 300h |

6 |

50 |

|

05 / U/S – R – U/S – R – F |

Ultrasonic / Rinse / Ultrasonic / Rinse / Oven |

700 x 500 x 300h |

14 |

105 |

|

05 / US – R – US – R – F |

Ultrasonic / Rinse / Ultrasonic / Rinse / Oven |

650 x 350 x 600h |

14 |

120 |

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

CATALOGUE MODELS MANUAL ULTRASONIC WASHERS WITH PLATFORM AND SLIDING TRANSLATION SYSTEM EPTA MAN LIFTER SERIES

|

Model series EPTA UNILIFT |

Washing line sequence |

Internal dimensions of tanks (mm) |

Unilift platform dimensions (mm) |

Unilift platform capacity (kg) |

Installed electrical power (KW) |

Single bowl capacity (lt) |

|

02 / US-RC |

Ultrasonic / Hot Rinse |

700 x 600 x 500h |

600×450 |

30 |

7,2 |

210 |

|

02 / US-RC |

Ultrasonic / Hot Rinse |

700 x 700 x 600h |

550×520 |

100 |

14,2 |

300 |

|

03 / US-RC-F |

Ultrasonic / Hot rinse / Hot air |

500 x 400 x 300 |

400 x 280 |

30 |

8 |

80 |