TNL series spray or ultrasonic cleaning and degreasing tunnels for parts

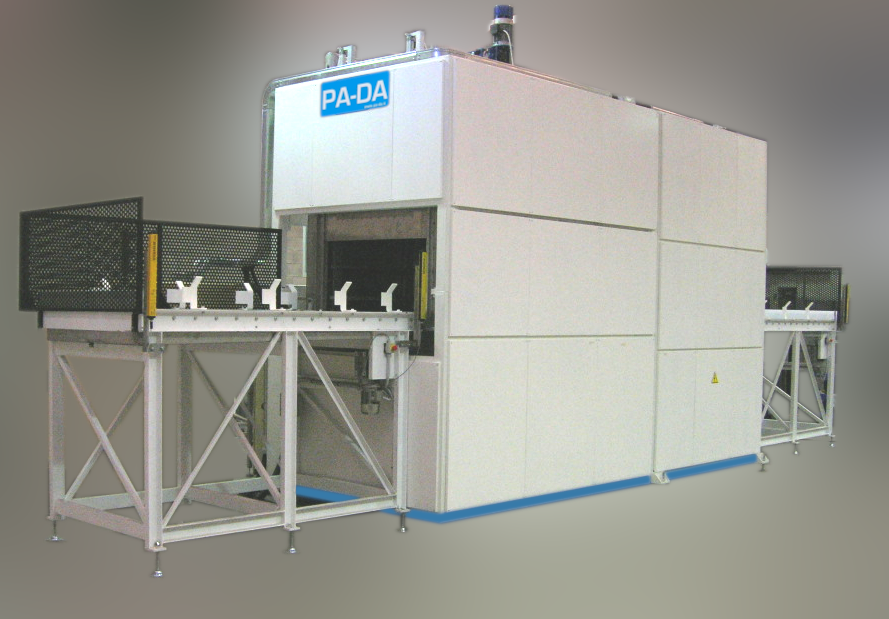

The TNL series spray or ultrasonic cleaning and degreasing tunnels are designed for the continuous treatment of parts and components, even large ones, placed in bulk on a conveyor belt or on attached supports. The cleaning action is performed by jets of water and detergent, positioned above, below, and to the sides of the parts, which strike them at high speed as they advance from the loading area to the unloading area. The dispensing ramps are fed with liquid from storage tanks beneath the work chamber. Our spray cleaning tunnels generally consist of multiple treatment sections; the typical configuration is degreasing, rinsing, and drying with ventilated air. The loading and unloading of the parts can be performed by the operator or by automated systems. Using the same type of part conveying, we also produce hybrid ultrasonic and spray cleaning tunnels. We offer standard models and customized solutions.

CONCESSIONS

INDUSTRY 4.0

INDUSTRY 5.0

KEY FEATURES

Spray ramps on all sides of the pieces

Possibility of ultrasonic immersion washing

Automated loading and unloading of parts

Drying with hot ventilated air

KEY FACTORS

CONTINUOUS FEEDING WITH PIECES POSITIONED IN BULK OR STEP-BY-STEP WITH PIECES POSITIONED

spray washing using fixed or mobile ramps or with immersion ultrasound

AUTOMATIC BYPASS FILTRATION. STEAM EXTRACTION AND CONDENSING SYSTEMS. ADJUSTABLE FEED SPEED.

TNL 6000

Hybrid cycle ultrasonic plus spray washing tunnel

TNL 10000

Washing tunnel for sheet metal 3 meters long and weighing 30 quintals